What type

of lean event should we do first, Value Stream Mapping (VSM) or Kaizen Burst?

Before we

can answer this question, let’s first define these two popular event types

Value Stream Mapping (VSM) – A multiple day

event (2-5 days) focused on mapping the process from customer order to customer

delivery. The goal is to complete a current state and future state map, then identify the 8 forms of waste that is keeping the process from achieving the future state.

Requires multi-disciplined participation from all stakeholders who impact, or

are impacted by the process. The deliverable is a list of projects, actions and

events that need to be completed in the next 6-12 months, with names and due

dates.

Kaizen Burst – Also called rapid process

improvement (RPI). A 3-5 day event focused on making dramatic improvements to a specific part of a process by the end of the event (focus is on implementation, not planning). Not

every action will be completed, but the goal is to have 80% of the actions

completed during the event, and the remaining 20% completed within 30 days of

the end of the event. The event should allow time to make adjustments in case the changes do not work. The goal is to make quick progress without pushing the waste to another department or area.

If you’re

just getting started with your process improvement in a process area or

department, I would highly recommend the kaizen burst event. The goal is to scope

the intent and purpose of the event, then do a considerable amount of work up

front (usually takes 1-2 weeks of preparation). During the event, the first

couple days are focused on getting everyone familiar with the preparation, and to

go and physically observe the current process, so everyone is aware of the wastes and

issues. The rest of the days are focused on implementation. It’s an action-driven

event. When you get done with the event, you have something to show for all

that work and time away from your regular job.

|

| Typical Kaizen Burst Workshop format, from Lean Enterprise Institute |

When you

pull people away from their job for 3 to 5 days, and you are just starting with

process improvement (Lean and Six Sigma), you want to have something to show

for all that time.

One of the

problems with VSM events is that they end with a list of actions items. Now in

order to see results from the event, you are asking those same people to spend

more time after the event to complete these tasks. Remember, they have already taken

time out of their work week. They are already behind with their regular work,

and will need time to catch up. Even though there is excitement after the

event, it’s not enough to carry into the following week. It requires a lot of

micro-managing and project management and “hounding” people. In addition, usually

only a handful of people get assigned tasks, and it is usually quite a few actions.

Don’t get

me wrong, I think VSM events are excellent, and great for getting multiple

departments and groups to understand the entire process, and get on the same

page. However, it is really just a good planning activity, and the event alone

does not result in any immediate improvement (other than networking and

knowledge of the value stream). In fact, it can takes months before the actions

results in any improvement.

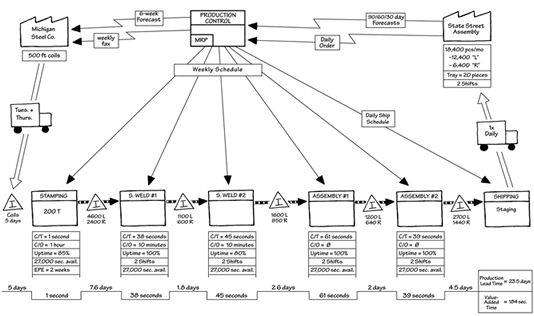

|

| Example of Value Stream Map |

But for

those getting started, or those that are needing major improvements, I would

highly recommend the kaizen burst event.

Both events

require upfront planning, but the kaizen burst requires more than the VSM,

since there may be major improvements taking place in a short amount of time.

Getting the right people involved is essential to success. That is why the

kaizen burst event needs leadership authorization to empower the team at the

start. In order to make these improvements, they must be allowed to try it out

without a lengthy approval process. Leaders must assign and delegate people to the team they

trust, or provide guidelines and rules that the team must stay within (such as

budget, procedures, etc).

Finally, a

kaizen burst usually involves the people doing the value-added work, more often

than VSM events, which seem to be too heavy on management. You want to engage those people as much as possible early on in a Lean Six Sigma journey,

since they are the ones who need to understand the concepts, and see the

immediate results applied to their work.

After the

process area has matured, or a couple kaizen bursts have been performed, then a

VSM event might be needed, when their primary problems are coming from outside

their area (outside their control). The idea is to “clean up your own

backyard” before you bring outsiders into the process.

In summary,

if the process area does not have a mature lean system (poor visuals, employees

not trained in lean, hard to see process flow, lots of inventory, poor labels,

lots of waste), then kaizen burst is the place to start.

What do you think? Do you agree? Share your comments below...